Vapor Intrusion

Overview

Sub Slab Depressurization Systems (SSDSs) and vapor barriers are used to counteract vapor intrusion of volatile organic compounds (VOCs) into occupied buildings and protect the health of residents and workers. Cooperstown is a leading expert in this emerging field. Our services range from site assessments of contamination to identify the need for an SSDS, to system design, construction, implementation, and operation. Hire Cooperstown – and breathe easier!

let’s talk possibilities:

Leaders in:

SSDS SSVS Vapor Intrusion Vapor Barriers Telemetry

Nothing is more important than the safety of the air we breathe. Unfortunately, environmental contamination is a common fact in our industrialized society. Releases of oil and hazardous materials from spills, tank leaks, past industrial disposal practices, or accidents have resulted in conditions that potentially can affect the health of residents and workers. Whether you live or work near a current or former gasoline station, dry cleaner, Brownfield site, or even a residence heated by oil, these chemicals could impact the safety of your indoor environment.

Cooperstown Environmental LLC is an acknowledged leader in the design, installation, and operation of a complete range of vapor intrusion solutions including SSDs, sub-slab ventilation systems, vapor barriers, and telemetry to protect against breathing contaminated vapors.

installing systems for:

PROPERTY OWNERS MANAGEMENT COMPANIES DEVELOPERS CONSTRUCTION FIRMS LENDERS LSPs LEPs

Cooperstown Environmental LLC is a leading expert in the analysis of site contamination and the design, implementation, construction, and operation of sub slab depressurization (SSD) systems. Our employees have significant, real-world experience; serve in leadership positions in the professional industry groups (including currently co-chairing the LSP Association’s Technical Practices Committee); and consult with the MassDEP and other industry colleagues on the latest practices. Cooperstown’s subject matter expert is Isaac Anderson, an acknowledged authority in the field who has provided numerous presentations to state and national audiences.

We have designed, installed, and/or consulted on sites across New England and the Mid-Atlantic states, providing mitigation services for over a million square feet of occupied space. Whether you need pre-design testing, plans and specifications, value engineering, installation, operations, maintenance and monitoring plans, or telemetry services, Cooperstown should be your first call for vapor intrusion expertise.

we perform:

Installations Design Telemetry Services Pilot Testing Diagnostics Troubleshooting System Maintenance

Cooperstown Environmental LLC consults across the entire range of issues associated with vapor intrusion mitigation – from beginning to end. Among our services are:

- Building Surveys & Pressure Testing

- Soil Gas Testing

- Indoor Air Testing

- Sub-Slab Pilot Testing (Pressure Field Extension Testing)

- Engineering & Design of Vapor Intrusion Mitigation Systems (VIMs)

- Installation of Active VIMs (a.k.a. SSDS)

- Installation of Passive VIMs (a.k.a. SSVS)

- Determination of Performance Standards

- Telemetry Installations, Testing, & Registrations

- Troubleshooting & Optimizing

- Operation, Maintenance & Monitoring (OM&M)Plans

- Vapor Barrier Design & Specification

- Vapor Barrier Installations

- Construction Administration

Frequently asked questions

Vapor intrusion (VI) occurs when vapors from volatile organic compounds (VOCs) in soil or groundwater enter a building through cracks, holes, utilities, or other penetrations in the foundation. When contaminant vapors enter into occupied spaces, whether residences or workplaces, occupants can be subjected to increased risks from these harmful vapors.

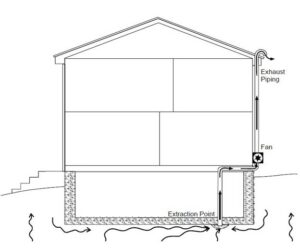

Conceptually, a sub slab depressurization or mitigation system is quite simple.

A pipe, typically PVC, is installed through the building’s concrete floor slab (or basement floor) to create a “vapor extraction point”. The vapor extraction point is then vented outside through the wall or roof. A blower or fan is then connected to the piping, which generates suction, creating a vacuum beneath the building. The vacuum draws in contaminated vapors from the subsurface soil and sends them up the pipe to the atmosphere, where they dissipate. Collectively, this is called a sub-slab depressurization system.

The system needs to be designed to ensure that the vacuum is strong enough to prevent vapors from entering the building. In certain scenarios, the system can operate passively (without the blower or fan), as a sub slab ventilation system.

Source: New Jersey Department of Environmental Protection

Depending on the chemical, the concentrations, and the flow rate, the air being vented from the system may require treatment (typically with granular activated carbon) prior to discharge.

A site investigation and engineering analysis must be performed as part of the vapor intrusion solution and be designed by competent experts. Subsurface gas transport is highly variable and can be strongly affected by the building’s construction, the presence of subsurface barriers (e.g., old foundation walls), mechanical ventilation, cooling and heating systems in the building, the condition of the floor slab, and other variables.

VI systems are similar to radon systems, which are common across the US and indeed, around the world. The primary difference between radon and VI systems are that a VI system is more engineered to result in a higher level of protection and address chemicals rather than a naturally-occurring gas.

The first step is to determine the location and concentrations of the chemicals in the subsurface. Then a pilot study or pressure field extension test using Pressure Points will determine how many extraction points are required, where they should be located, and what flow rate and vacuum is needed to ensure full protection. When properly designed, installed, and operated, these vapor intrusion systems are fully capable of rendering indoor air concentrations of the contaminants to below detectable levels. Cooperstown has scores of successful projects where our services have secured the safety of building occupants. A sub slab depressurization system (SSDS) is a proven, effective solution to ensure that occupied spaces remain safe for humans and pets.

Research has shown that exposure to contaminants by breathing the indoor air often is a greater health threat than direct skin contact to contaminants in the soil or even from drinking contaminated groundwater. For that reason, the disposal site cleanup standards set by the Massachusetts Department of Environmental Protection (DEP) are very conservative. In Massachusetts, the Massachusetts Contingency Plan (MCP) regulations dictate that Licensed Site Professionals (LSPs) – professionals trained and licensed by the state to oversee site cleanups – consider indoor air contamination as part of the site closure process. Other nearby states including Connecticut, New Hampshire, and Rhode Island have similar regulatory requirements intended to protect residents and workers.

Regulations set by the states have led to a vast increase in the need for SSDSs and vapor barriers over the past several years. A professional specializing in vapor intrusion services is often brought in to design and install the optimal vapor intrusion solution.

Cooperstown has extensive experience in designing, installing, and optimizing vapor intrusion solutions.

Telemetry units allow remote monitoring of the SSDS and notify the property owner and the regulatory agency if the SSDS malfunctions. Notification of a problem signals the owner to restore the system to service, thereby providing the intended protection to building occupants.